- Sun Oct 16, 2005 11:10 pm

#69593

Ok, what I have learned about metals is that since they contain so many free (or almost free) electrons, these electrons form an electromagnetic "barrier" so that photons reaching it do not penetrate it, like with plastics, but instead metals have the property that they reflect almost all the light they recieve. This and the fact that any specular highlights will be tinted in the metals color, unless the lightsource is very bright, then you will get a burn-out, or white specular.

Plastics on the other hand can absorb some of the light, light can penetrate plastic and the specular it returns is the color of the lightsource.

Now, what I'm trying to tell you is that in real life metals don't have a "metal" diffuse and then a "normal" specular reflection.

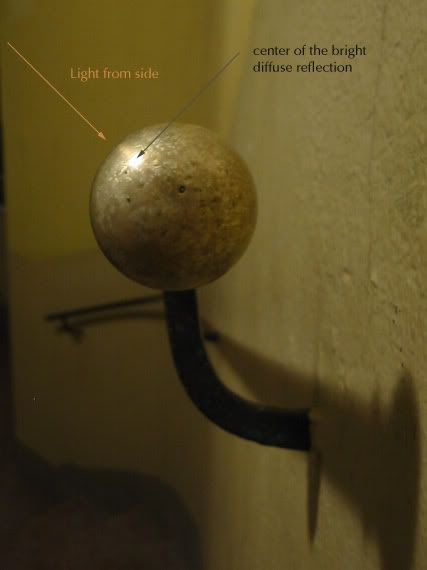

In your last example you say the reflections are not blurred. Yes they are! ALL materials have roughness. We have yet to construct a perfect mirror surface. They show a bit of blur, because of the micro grooves in that metal. What gives metal the ability to still look like it has a pretty sharp reflection is the fact that it reflects almost all of the light it recieves, there is no deep penetration and scattering like you get with plastics, which contribute to the effect that plastics will tend to look blurrier than metals even if they are very smooth.

A big part of that glow you mentioned can be attributed to the coloration of the reflected light that metals give you, except if the lightsource is strong enough like I said. You can see it in your last example as well, look at the edges of the white spot, they start to tint yellow.

The other part of that glow effect you see on worn metals is due to the deposits of very thin sheets of other substances which reflect some of the light back (in different directions, thus making a blurry reflection), but letting some light penetrate through to the metal, where it will give you that little bit sharper reflection. Or the metal suffers from oxidation, in which case I think that outer layer of oxidized metal contains less free electrons which lets light penetrate it deeper thus scattering it around before being reflected back=blurrier reflections. Polish the metal and you remove that thin sheet, you expose the clean metal=sharper reflections. But with polishing you will also increase anisotropic effect.

So there is no separate component in clean metals that give it a sharp reflection, and another one that give it blurrier reflections, or "glow". This is how we must think in Maxwell as well.

Why not take advantage of describing these properties accurately instead of creating fakes which do not exist? I think doing that we will quickly find ourselves in an impasse.

I don't see a big problem with layering a material, so you have a base, very reflective metal, and if you want on top of that to have a worn out blurrier look, add another layer.

Maxwellzone.com - tutorials, training and other goodies related to Maxwell Render

Youtube Maxwell channel

- By Gaspare Buonsante 20200309160206

- By Gaspare Buonsante 20200309160206